Why Hybrid Model Production Delivers Higher Detail, Realism, and Efficiency

The way physical scale models are created has transformed dramatically in recent years. While a skilled model builder remains invaluable for crafting precise, visually compelling pieces, digital fabrication has revolutionized the speed and complexity of what can be produced. Designers no longer need to choose between artistry and efficiency—hybrid methods make it possible to leverage both strengths, creating results that satisfy both technical and aesthetic expectations. This combination ensures that a project not only meets specifications but also communicates its design intent in the most effective way.

An architectural model is more than just a miniature version of a building; it is a storytelling device. Stakeholders, clients, and construction teams rely on these representations to understand how spaces interact, how light moves, and how proportions feel in real life. When manual craftsmanship is paired with modern techniques such as 3D printing, the result is a model that balances tactile detail with structural accuracy. Designers gain flexibility, allowing them to iterate quickly while maintaining a human touch.

For studios aiming to push boundaries in design visualization, integrating digital and traditional workflows is no longer optional—it’s essential. The nuances added by human hands elevate the realism of a project, while automated fabrication ensures that complex geometries, repetitive elements, and technically precise parts are executed flawlessly. Together, these methods streamline the production process without sacrificing the artistry that defines standout models.

How 3D Printing Supports Traditional Craft

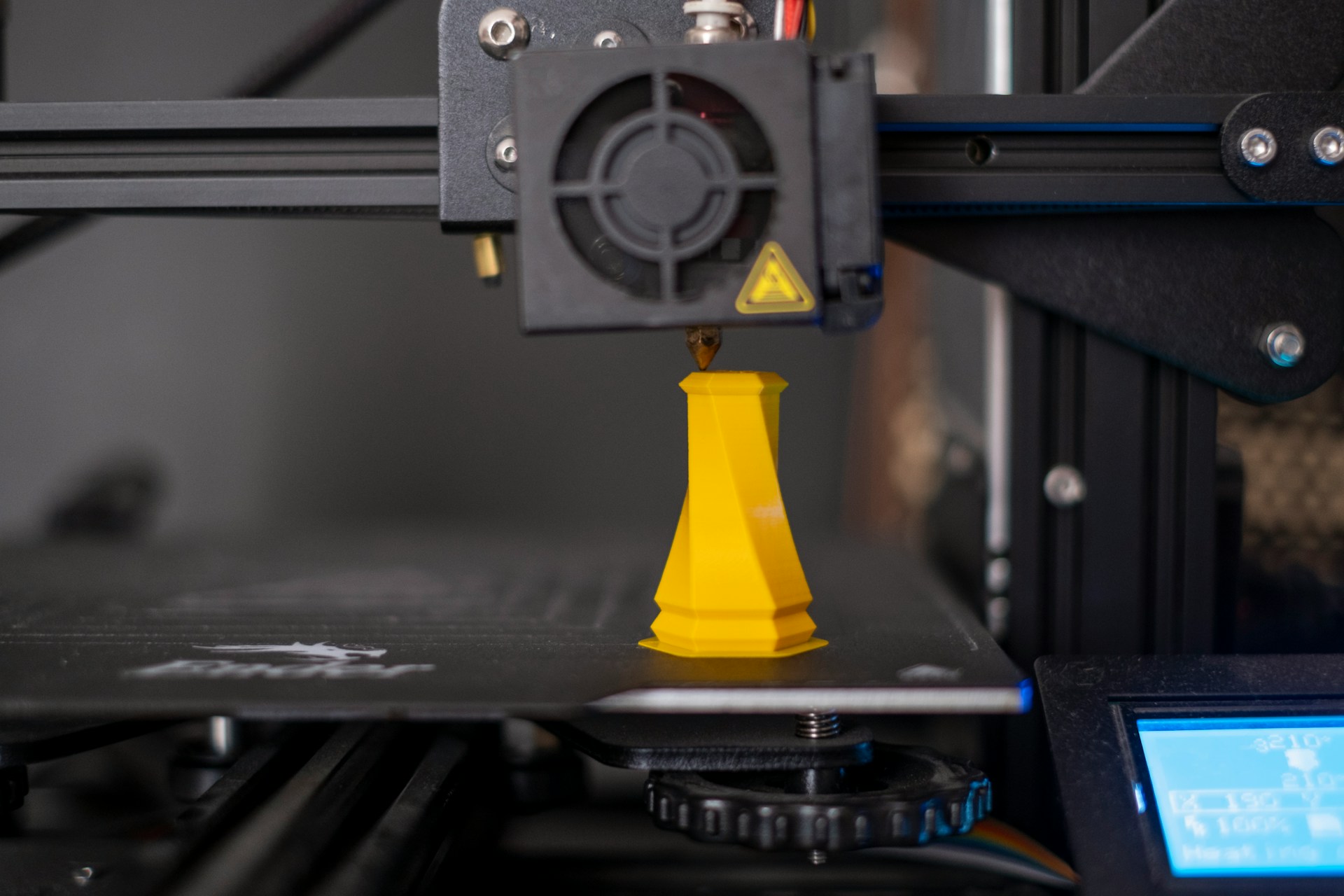

3D printing has changed the way designers approach complex scale models. Shapes that once required hours of manual labor can now be produced with pinpoint precision, saving time and reducing the risk of errors.

Some advantages of incorporating digital components into a physical model include:

-

The ability to fabricate intricate structures that would be nearly impossible by hand

-

Consistent repetition of elements such as columns, railings, or façade patterns

-

Rapid iteration for client revisions without compromising quality

-

Reduced material waste due to precise calculations

Even when relying on automated production, the presence of a skilled model builder ensures that these pieces are integrated seamlessly into the larger assembly. The precision of digital fabrication complements the organic nuances of hand-applied detailing.

Steps to Achieve a Hybrid Model Workflow

Combining traditional techniques with digital fabrication requires careful planning. A structured workflow helps teams maximize efficiency while preserving quality. A typical process could include:

-

Concept development and initial sketches

-

Translating the concept into digital files for complex or repetitive components

-

Fabricating critical elements using 3D printing or CNC cutting

-

Manual construction of unique textures, landscaping, and finishing touches

-

Assembly and final refinement, ensuring all pieces align visually and structurally

Following a clear sequence reduces errors and ensures that both human and digital contributions enhance the final architectural model.

Why Manual Skills Remain Indispensable

While automated methods increase speed, the tactile expertise of a model builder brings irreplaceable value. Techniques like sanding, layering, painting, and sculpting provide depth and realism that machines cannot replicate. These subtle details often influence how viewers perceive a project, making a model feel more immersive and lifelike.

Manual craftsmanship excels in areas such as:

-

Adding natural variation to terrain or landscaping

-

Adjusting elements for visual balance and proportion

-

Creating textures that mimic real-world materials

-

Incorporating delicate or irregular features that digital tools struggle to capture

This human touch enhances the overall visual appeal, making models more engaging for clients and stakeholders alike.

The Impact of Layered Techniques

A hybrid approach allows designers to layer digital and handcrafted elements to create richer visual experiences. Digitally produced parts provide structure and accuracy, while handcrafted details add realism and artistic nuance.

Examples of effective layering include:

-

Precision-cut windows and façades combined with hand-painted textures

-

3d printed structural frameworks surrounded by manually applied landscaping

-

Repetitive elements generated digitally, complemented by unique hand-finished features

These combinations provide a model that is technically sound, visually compelling, and capable of telling a detailed story about the project’s design.

Accelerating Timelines Without Sacrificing Quality

Hybrid workflows are particularly beneficial when time is a critical factor. Digital fabrication accelerates the production of complex or repetitive components, allowing manual efforts to focus on areas that require artistic input. This approach ensures projects meet tight deadlines while maintaining a high level of craftsmanship.

Additional benefits include:

-

Easier revision of elements when client requests changes

-

Reduced material waste through precise digital fabrication

-

Consistent quality across multiple versions of the same design

-

Smoother collaboration between designers, digital operators, and model builders

By leveraging both approaches, teams achieve faster delivery without compromising the realism or accuracy of the architectural model.

Collaborative Workflows for Better Results

Bringing together digital specialists and skilled craftsmen creates a more dynamic and effective team. Collaboration allows for problem-solving in real time, creative iteration, and improved communication.

Key aspects of a collaborative workflow:

-

Digital operators handle technical elements and repetitive structures

-

Model builders focus on visual detailing, textures, and finishing touches

-

Designers coordinate both sides, ensuring that the final product aligns with the original vision

This balance ensures that the hybrid method remains productive while preserving the artistic quality that clients value.

Creating Models That Engage and Inspire

The ultimate advantage of combining traditional and digital methods lies in the finished product. When executed effectively, the architectural model feels accurate, immersive, and expressive. Viewers can appreciate both the precision of technical components and the tactile richness of hand-applied elements.

This approach demonstrates that speed and creativity are not mutually exclusive. Teams that embrace hybrid workflows consistently deliver models that:

-

Communicate design intent clearly

-

Capture attention with detailed craftsmanship

-

Allow clients to visualize space and material choices effectively

-

Adapt quickly to changes or new requirements

By balancing artistry with technology, designers create scale models that impress, inform, and inspire.